PRODUCT DESCRIPTION

LUFT300-L explosion-proof integrated thermal imaging camera is composed of infrared thermal image thermometer, visible light camera and integrated explosion-proof head. The product has the highest level of explosion-proof certification, can be used in places with class ⅡA, ⅡB, ⅡC combustible gas, ignition temperature group T1-T6 group 1, 2 zone, flammable gas or vapor and air formed explosive mixture, or suitable for ignition temperature group T1-T6 group 20~22 zone, containing combustible dust mixture. Products support ONVIF and other standard protocols, and provide SDK, easy to integrate with third-party platform software, suitable for petrochemical plants, hazardous chemical storage and transportation, coal, oil Wells and other fields.

- INTRODUCE

- Technical features

- Technical specification

- Apply

LUFT300-L explosion-proof integrated thermal imaging camera is composed of infrared thermal image thermometer, visible light camera and integrated explosion-proof head. The product has the highest level of explosion-proof certification, can be used in places with class ⅡA, ⅡB, ⅡC combustible gas, ignition temperature group T1-T6 group 1, 2 zone, flammable gas or vapor and air formed explosive mixture, or suitable for ignition temperature group T1-T6 group 20~22 zone, containing combustible dust mixture. Products support ONVIF and other standard protocols, and provide SDK, easy to integrate with third-party platform software, suitable for petrochemical plants, hazardous chemical storage and transportation, coal, oil Wells and other fields.

According to relevant statistical data, gas leakage conforms to the "28 principle", that is, 80% of the leakage is caused by 20% of the leakage points.

With increasing regulation of environmental laws around the world, oil and gas producers are looking for ways to quickly detect runaway emissions and stop these leaks before they turn into huge fines.

Signal Optical Gas Imaging thermography machines are certified for use in hazardous locations, so inspectors can work with confidence. By finding leaks and fixing them quickly, your company can both protect the environment and avoid the loss of product and the cost of regulatory fines for polluting the environment.

Detect small leaks quickly

Equipped with an optical gas imaging thermal camera, even the smallest concentrations of methane, hydrocarbons, and volatile organic compounds (VOCs) can be visualized and surveyors can get to work immediately, finding leaks several times faster than traditional gas sniffing methods.

Multi-scenario application

The product can be equipped with a protective head, mounted on the vertical pole or the tower, which can realize a wide range of remote detection in the chemical industry park.

The products can be matched with explosion-proof robots, which can realize regular inspection of production facilities in chemical plants and improve inspection efficiency.

The product can be paired with drones or motor vehicles, which can assist emergency fire accident handling and provide decision data for the development of emergency handling measures.

• Explosion-proof class: ExdⅡC T6 Gb/Ex tD A21 IP68 T80℃

• The infrared thermal imager can be selected with different resolutions, different lens focal lengths and temperature measurement function

• Visible light cameras can be selected with different resolutions and different lens focal lengths

• Pinion adopts high-precision stepper motor with worm gear drive, horizontal direction 360° continuous rotation, vertical direction -90° (down) ~ 90° (up), no monitoring blind area

• 304 stainless steel design

• The network supports standard protocols such as ONVIF/RTSP and provides an SDK for easy integration with third-party platform software

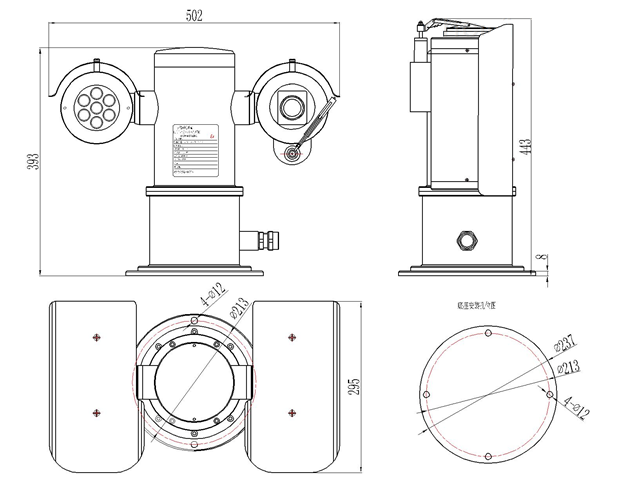

• Size: 502mm*295mm*451mm

Infrared thermal image thermometer

• Detector type

Vanadium oxide (VOx) infrared microbolometer

• Resolution/pixel spacing

384*288/17um, 640*512/17um

• Thermal sensitivity

≤ 40mK@F /1.0, ≤ 40mK@F /1.0

• Focal length (optional)

19mm/25mm/35mm, both electric focus lenses

• Temperature range

-20℃~+150℃ (can be extended to -20℃~+350℃)

• Temperature measurement accuracy

±2 ° C or ±2%, the largest value

• Temperature measurement mode

Real-time cursor temperature, high and low temperature tracking, average temperature points, lines, surfaces

Visible light camera

• Sensor type

1/2.8 inch COMS; 1/1.8 inch COMS

• Resolution

2 million /3 million /5 million (optional)

• Optical magnification

20x / 30X / 36X / 50x (optional)

Holder

• Head rotation Angle

Horizontal 360° continuous rotation, vertical -90°~90°

• Head rotation speed

Horizontal 0.1°/S~35°/s, vertical 0.1°/S~35°/s

• Automatic cruise speed

Horizontal 10°/s, vertical 10°/s

• PTZ positioning accuracy

Position deviation ≤0.1°

Physical characteristics

• Volume (H*W*L)

502mm*295mm*451mm

• Product weight

≤26kg

• Product material

304 stainless steel (chemical, acid, alkali and other strong corrosion environment)

Petrochemical plant: The product can be used in the thermal fault detection of plant equipment, the product uses visible light and infrared fusion image, can quickly find the fault area.

Fire rescue: petrochemical plant containing flammable and explosive items, easy to fire. At the scene of a fire, firefighters often cannot see the injured because of too much smoke, thus missing the best rescue opportunity. Fire personnel can use the product, using the product's smoke permeability function, can quickly and accurately find trapped people, timely save lives.